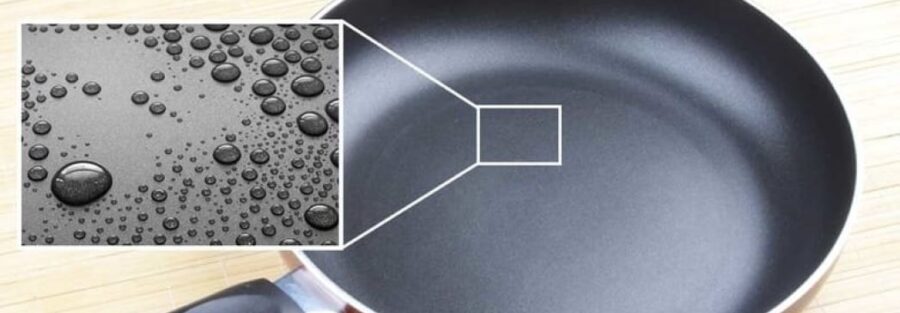

Non-Stick Teflon Coating for Industrial While Teflon is widely recognized for its household applications, particularly in non-stick cookware, its industrial applications showcase a far broader and more critical range of benefits. Non-stick Teflon coating for industrial use represents a powerful engineering solution that goes beyond preventing food from sticking; it offers a unique combination of properties that enhance efficiency, reduce maintenance, and improve the lifespan of critical industrial components.

What sets industrial Teflon coating apart is its exceptional ability to provide a surface where virtually nothing adheres. This fundamental characteristic unlocks a cascade of advantages that are crucial across diverse industrial sectors.

The Unique Power of Non-Adhesion:

Non-Stick Teflon Coating for Industrial The core uniqueness of industrial Teflon coating lies in its remarkably low coefficient of friction and its inherent non-wetting properties. This means:

- Non-Stick Teflon Coating for Industrial Minimal Sticking: Substances like adhesives, paints, chemicals, powders, and even molten materials have a significantly reduced tendency to stick to Teflon-coated surfaces. This prevents buildup, clogging, and contamination, leading to smoother operations and higher product quality.

- Non-Stick Teflon Coating for Industrial Effortless Release: When contact does occur, the release is remarkably easy. This simplifies cleaning processes, reduces downtime for maintenance, and allows for the efficient transfer of materials without residue.

- Non-Stick Teflon Coating for Industrial Low Friction: The exceptionally low coefficient of friction minimizes resistance between moving parts. This translates to reduced energy consumption, lower wear and tear on equipment, and quieter operation.

Non-Stick Teflon Coating for Industrial Beyond Non-Stick: A Spectrum of Industrial Advantages:

The unique non-stick property of Teflon coating acts as a foundation for a multitude of other valuable characteristics in industrial settings:

- Chemical Resistance: Teflon is inherently inert and resistant to a vast array of corrosive chemicals, solvents, and acids. This makes it an ideal protective layer for equipment operating in harsh chemical environments, extending their operational life and reducing the risk of material degradation.

- High and Low Temperature Performance: Industrial Teflon coatings can withstand a wide range of temperatures, from cryogenic levels to well over 200°C (400°F), depending on the specific formulation. This thermal stability ensures reliable performance in demanding thermal conditions.

- Electrical Insulation: Certain Teflon formulations exhibit excellent dielectric properties, making them suitable for electrical insulation applications, preventing short circuits and ensuring the safe operation of electrical equipment.

- Wear and Abrasion Resistance: While primarily known for its non-stick properties, specialized industrial Teflon coatings can be engineered to offer significant resistance to wear and abrasion, protecting underlying materials from damage caused by friction and impact.

- Cleanability and Hygiene: The non-porous and non-stick nature of Teflon surfaces makes them exceptionally easy to clean and sanitize. This is crucial in industries like food processing and pharmaceuticals, where maintaining strict hygiene standards is paramount.

Diverse Industrial Applications: A Testament to Versatility:

The unique properties of industrial Teflon coating make it indispensable across a wide spectrum of industries:

- Manufacturing: Coating molds for easy release of plastic and rubber parts, lining chutes and hoppers for smooth material flow, protecting conveyor belts from sticky substances.

- Chemical Processing: Lining tanks, pipes, and reactors to resist corrosion and prevent contamination.

- Food Processing: Coating baking trays, conveyor belts, and processing equipment for easy release and hygienic operation.

- Packaging: Coating heat-sealing bars to prevent film sticking and ensure efficient sealing.

- Textiles: Coating rollers and guides to prevent yarn sticking and ensure smooth fabric processing.

- Aerospace: Coating fasteners and components to prevent seizing and corrosion in extreme environments.

- Medical: Coating surgical instruments for smooth operation and easy cleaning.

In Conclusion: A Unique Solution for Industrial Challenges:

Non-stick Teflon coating for industrial use is far more than just a slippery surface. It’s a unique engineering material that offers an unparalleled combination of non-adhesion, chemical inertness, thermal stability, and other beneficial properties. This versatility allows it to address a wide range of challenges across diverse industrial sectors, leading to increased efficiency, reduced maintenance costs, extended equipment lifespan, and improved product quality. The unique characteristics of industrial Teflon coating make it an indispensable tool for optimizing industrial processes and ensuring reliable performance in demanding environments.