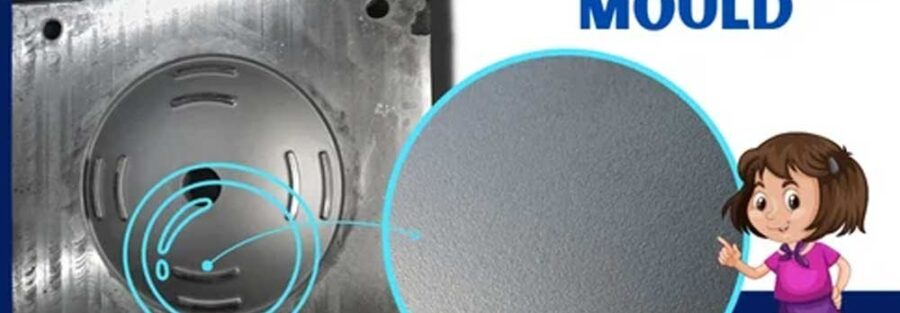

Mould Texturing Services In the world of manufacturing, especially within industries reliant on moulding processes, the final product is often only as good as the mould it came from. This is where mould texturing services play a crucial, yet often underappreciated, role. It’s the art and science of adding specific patterns, grains, or designs to the surface of a mould, ultimately transferring these features onto the finished product. But it’s more than just aesthetics; it’s about functionality, quality, and even brand identity.

Understanding the Value of Mould Texturing Services:

Think of a plastic part, like the interior trim of a car, a medical device casing, or even a simple toy. The smooth, tactile, or visually appealing surface you see isn’t a mere coincidence. It’s the result of carefully executed mould texturing. Mould texturing services provide the expertise and specialized techniques to achieve these desired surface finishes.

| Laser Texturing | Precise laser ablation for complex 3D effects. | High accuracy and control over texture. | |||

| EDM (Electrical Discharge Machining) | Electrical spark erosion for hard materials. | Ideal for hard materials and complex shapes. | |||

| Mechanical Texturing | Physical alteration for coarser textures. | Effective for robust and durable textures. | |||

| Polishing & Finishing | Achieving specific surface smoothness and gloss. | Enhances product appearance and feel. | |||

| Applications | Automotive | Interior trims, exterior components. | Improved aesthetics and functionality. | ||

| Consumer Electronics | Casings, user interfaces. | Enhanced grip and visual appeal. | |||

| Medical Devices | Surgical instruments, medical equipment. | Ensures safety and usability. | |||

| Packaging | Bottles, containers, closures. | Improves brand image and product handling. | |||

| Toys & Sporting Goods | Toys, sporting equipment. | Enhances safety, performance, and aesthetics. | |||

| Choosing a Service | Experience & Expertise | Proven track record and industry-specific knowledge. | Reliable and competent service provider. | ||

| Technological Capabilities | Advanced equipment and techniques. | Ability to handle complex projects. | |||

| Quality Control | Robust quality assurance processes. | Consistent and high-quality results. | |||

| Turnaround & Pricing | Meets project timeline and budget. | Timely and cost-effective solutions. |

Why Seek Professional Mould Texturing Services?

- Expertise and Precision: Specialized service providers possess the knowledge, experience, and advanced equipment to handle various texturing techniques, ensuring consistent and precise results.

- Customization and Design Flexibility: Whether it’s a specific grain pattern, a logo, or a unique texture for enhanced grip, these services can bring your design vision to life.

- Enhanced Product Functionality: Texturing can improve grip, reduce glare, enhance wear resistance, and even mask imperfections, ultimately improving the product’s performance and longevity.

- Improved Aesthetics and Brand Identity: A well-executed texture can elevate the perceived quality of a product and contribute to a stronger brand image.

- Time and Cost Efficiency: Outsourcing mould texturing to professionals can save time and resources compared to investing in in-house equipment and training.

- Access to Advanced Techniques: Service providers often offer a wider range of texturing techniques, including chemical etching, laser texturing, EDM, and mechanical methods, catering to diverse needs.

The Range of Services Offered:

Professional mould texturing services typically offer a comprehensive range of techniques, including:

- Chemical Etching: For intricate patterns and varying depths.

- Laser Texturing: For precise control and complex designs, including 3D effects.

- Electrical Discharge Machining (EDM): For hard materials and complex shapes.

- Mechanical Texturing: For coarser textures and specific geometric patterns.

- Polishing and Finishing: To achieve specific surface smoothness and gloss levels.

Applications Across Industries:

Mould texturing services cater to a wide range of industries, including:

- Automotive: For interior and exterior components, enhancing aesthetics and functionality.

- Consumer Electronics: For casings, housings, and user interfaces, improving grip and visual appeal.

- Medical Devices: For surgical instruments and medical equipment, ensuring safety and usability.

- Packaging: For bottles, containers, and closures, enhancing brand image and grip.

- Toys and Sporting Goods: For safety, performance, and aesthetic appeal.

Choosing the Right Service Provider:

When selecting a mould texturing service provider, consider factors such as:

- Experience and Expertise: Look for a provider with a proven track record and expertise in your specific industry.

- Technological Capabilities: Ensure they have the necessary equipment and expertise to handle your project’s complexity.

- Quality Control: Inquire about their quality assurance processes to ensure consistent and high-quality results.

- Turnaround Time and Pricing: Discuss your project timeline and budget to find a provider that meets your needs.

In conclusion, mould texturing services are an essential component of modern manufacturing, offering expertise and precision to enhance the functionality, aesthetics, and overall quality of moulded products. By partnering with a reputable service provider, businesses can elevate their products and gain a competitive edge in the marketplace.