The Art of Texture: Media Blasting for Car Molds

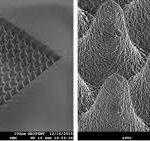

Media Blasting For Car Molds When you run your hand across the dashboard or door panel of a car, you often encounter more than just a smooth surface. You feel a deliberate texture – perhaps a subtle grain, a geometric pattern, or even a rugged stippling. This texture isn’t just for aesthetics; it plays a crucial role in reducing glare, improving grip, and enhancing the overall tactile experience.1 So, how do automotive manufacturers achieve these intricate surface finishes on the molds used to create these interior components? The answer often lies in a versatile technique called media blasting.

Media Blasting For Car Molds Think of media blasting as a highly controlled form of abrasion. Instead of using sandpaper or a grinding wheel, this process employs a stream of fine particles, propelled at high speed towards the surface of the car mold. These particles, known as the media, come in a wide variety of materials, sizes, and shapes, each capable of producing a unique textural effect.2

How Does it Work? Media Blasting For Car Molds

Media Blasting For Car Molds Imagine a tiny sandstorm, precisely directed. A specialized machine forces compressed air to propel the chosen media through a nozzle. The operator carefully directs this stream onto the mold surface. As the media impacts the mold, it gently etches away microscopic layers of material. By controlling factors like the type of media, the air pressure, the distance from the nozzle, and the angle of attack, skilled technicians can achieve a remarkable range of textures.

The Unique Advantages of Media Blasting For Car Molds

Why is media blasting such a popular choice for texturing car molds? It boils down to a unique combination of benefits:

- Versatility in Texture: This is where media blasting truly shines. By simply switching the type of media – from fine glass beads to coarse aluminum oxide or even organic materials like crushed walnut shells – manufacturers can create everything from a delicate matte finish to a deeply textured, non-slip surface. Each media imparts a distinct characteristic to the mold.

| Feature | Description | Benefits | Examples/Details |

| Process Overview | A controlled abrasion technique using a high-speed stream of fine particles (media) to etch the surface of car molds. | Precise control over texture, ability to create intricate details and complex geometries. | Compressed air propels media (glass beads, aluminum oxide, etc.) through a nozzle onto the mold surface. Parameters like media type, pressure, and distance are crucial. |

| Texture Versatility | Wide range of textures achievable by simply changing the type of media used. | Allows for diverse aesthetic and functional outcomes, from subtle matte finishes to aggressive grip surfaces. | Glass beads for smooth/satin finishes, aluminum oxide for rougher textures, organic media for softer effects. |

| Consistency & Repeatability | Once parameters are set, the process yields highly consistent results across multiple molds. | Ensures uniformity in the final product, crucial for mass production and maintaining brand standards. | Automated blasting systems contribute to high repeatability. Consistent media supply and pressure control are vital. |

| Intricate Details | The focused media stream can access and texture complex curves and fine features of the mold. | Enables more visually appealing and ergonomically designed interior components that might be challenging with traditional methods. | Texturing around buttons, contours of dashboards, and detailed patterns on door panels. |

| Cost-Effectiveness | Can be a relatively cost-effective solution, especially for large production runs. | Quick processing times and the potential for automation contribute to lower per-unit costs. | Initial equipment investment vs. long-term operational costs and reduced manual labor. |

| Environmental Aspects | Growing availability of eco-friendly media options and the use of containment and filtration systems. | Reduces environmental impact compared to some traditional abrasive methods. | Biodegradable media (walnut shells, corn cobs), closed-loop blasting systems to recycle media and capture dust. |

| Functional Importance | Texture serves purposes beyond aesthetics. | Reduces glare, improves grip on frequently touched surfaces, enhances scratch resistance, and can provide tactile feedback. | Textured dashboards to minimize sun reflection, textured steering wheels for better handling, textured door panels to hide minor scuffs. |

| Media Types & Effects | Different materials produce distinct surface finishes. | Allows for tailoring the texture to the specific requirements of the car component. | Glass Beads: Smooth, peened. Aluminum Oxide: Rough, matte. Silicon Carbide: Very aggressive. Plastic Media: Gentle cleaning/softer textures. Organic Media: Soft, less abrasive. |

- Consistent and Repeatable Results: Unlike manual texturing methods, media blasting offers a high degree of consistency. Once the optimal parameters are established, the process can be reliably repeated across multiple molds, ensuring uniformity in the final product. This is crucial for maintaining quality and brand identity in mass production.

- Intricate Detail and Complex Geometries: The focused stream of media can reach into intricate details and complex curves of the mold, allowing for texturing in areas that might be difficult to access with traditional methods. This opens up design possibilities for more visually interesting and ergonomically enhanced interior components.

- Cost-Effectiveness: Compared to some other texturing processes, media blasting can be a cost-effective solution, especially for large production runs.3 The process is relatively quick, and the equipment, while specialized, offers good long-term value.

- Environmentally Conscious Options: While traditional abrasive blasting can raise environmental concerns, advancements in media blasting have led to the development of more eco-friendly media options, such as biodegradable materials. Proper containment and filtration systems further minimize environmental impact.4

The Media Spectrum: A Palette of Textures Media Blasting For Car Molds

The secret to the versatility of media blasting lies in the diverse range of media available. Here are a few examples and the textures they typically create:

- Glass Beads: Produce a smooth, peened, or satin finish, often used for a subtle sheen or for cleaning without aggressive abrasion.5

- Aluminum Oxide: A harder abrasive, ideal for creating more aggressive textures, such as those found on grip surfaces.6 The grit size determines the roughness.

- Silicon Carbide: An even harder and sharper media, used for creating very aggressive textures or for material removal.7

- Plastic Media (e.g., Acrylic, Urea): Softer media options used for delicate surfaces or for removing coatings without damaging the underlying material. They can create a softer, less aggressive texture.

- Organic Media (e.g., Walnut Shells, Corn Cobs): Biodegradable options often used for cleaning or creating softer, less abrasive textures.

Beyond Aesthetics: The Functional Importance of Media Blasting For Car Molds

While the visual appeal of textured car interiors is undeniable, the texturing process achieved through media blasting also serves important functional purposes:

- Glare Reduction: Textured surfaces diffuse light, reducing unwanted glare that can distract the driver.8

- Improved Grip: On steering wheels, gear knobs, and other frequently handled parts, texture enhances grip and prevents slippage.9

- Scratch Resistance: Textured surfaces can help to conceal minor scratches and scuffs that might be more noticeable on a perfectly smooth surface.10

- Tactile Feedback: Different textures can provide subtle tactile cues, enhancing the user experience.

In Conclusion:

Media blasting is a sophisticated and indispensable technique in the creation of textured car molds. Its ability to deliver a wide spectrum of consistent, repeatable, and intricate textures, coupled with its cost-effectiveness and growing range of environmentally conscious options, makes it a cornerstone of modern automotive interior design and manufacturing. The next time you appreciate the feel and look of your car’s interior surfaces, remember the precise and powerful process of media blasting that helped bring that texture to life.