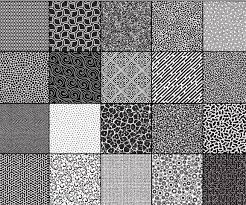

Car Mold Surface Textures Step inside any modern vehicle, and you’ll be surrounded by a symphony of textures. From the smooth sweep of the dashboard to the patterned grip of the steering wheel and the subtle grain of the door panels, these surface finishes are far from accidental. They are meticulously engineered into the car molds themselves, playing a crucial role in both the aesthetic appeal and the functional performance of the vehicle’s interior and exterior components.

More Than Just Smooth or Rough:

Car Mold Surface Textures go beyond simply being smooth or rough. They encompass a vast spectrum of patterns, grains, and finishes, each designed with a specific purpose in mind. These textures are not applied as an afterthought; they are intricately incorporated into the very surface of the molds used to create plastic, composite, and even some metal car parts.

Think of the mold as a stamp. Any detail present on the surface of this stamp will be faithfully replicated on the parts it produces. This includes even the most minute textures. Therefore, the creation of these textures on the mold surface is a critical step in the manufacturing process.

Why are Surface Textures So Important in Cars?

Car Mold Surface Textures The application of specific textures to car parts is driven by a multitude of factors:

- Aesthetics and Design: Textures significantly contribute to the perceived quality and visual appeal of a vehicle’s interior and exterior. Different grains and patterns can evoke feelings of luxury, sportiness, ruggedness, or modernity. Designers carefully select textures to align with the overall design language of the car.

- Tactile Experience: The way a surface feels to the touch is crucial for user interaction. Textured surfaces on steering wheels, gear knobs, and control buttons provide better grip and a more satisfying tactile feedback.

- Durability and Scratch Resistance: Certain textures can help to conceal minor scratches and wear and tear that occur over time, maintaining the aesthetic integrity of the components. A slightly textured surface is often more forgiving than a perfectly smooth, glossy one.

- Light Diffusion and Glare Reduction: Textured surfaces can diffuse light, reducing unwanted glare from sunlight or interior lighting, improving visibility and driver comfort.

- Acoustic Properties: Specific textures can influence the way sound waves interact with surfaces, contributing to the overall acoustic comfort within the cabin by absorbing or scattering sound.

- Paint Adhesion: In some exterior applications, a subtle texture on the plastic part can improve the adhesion of paint layers, ensuring a more durable and long-lasting finish.

- Functionality (e.g., Anti-Slip): Textured surfaces in areas like the floor mats or pedal covers are essential for providing grip and preventing slippage, enhancing safety.

How are These Textures Created on Car Molds?Car Mold Surface Textures

Car Mold Surface Textures Creating these precise textures on the surface of car molds is a specialized process involving various techniques:

- Chemical Etching: This is a common method for creating intricate and consistent grain patterns. The mold surface is treated with chemicals that selectively erode areas protected by a mask, leaving behind the desired texture. Different chemicals and masking techniques can produce a wide variety of grains.

- Laser Texturing: High-precision lasers are used to ablate material from the mold surface, creating complex and customizable textures. This method offers great flexibility and control over the texture design.

- Mechanical Engraving: Specialized tools are used to physically cut or engrave the desired pattern into the mold surface. This technique is often used for creating more defined and geometric textures.

- Electroforming: A thin layer of metal with the desired texture is deposited onto a master pattern using electroplating. Car Mold Surface Textures This textured metal layer is then incorporated into the mold.

- Direct Metal Laser Sintering (DMLS) / Additive Manufacturing: For certain mold inserts, complex textures can be directly “printed” layer by layer using metal powders and lasers, offering intricate and organic texture possibilities.

The Importance of Precision and Consistency:

Regardless of the method used, achieving precise and consistent texture across the entire mold surface is paramount. Any variation in the texture can lead to inconsistencies in the appearance and feel of the final car parts, impacting perceived quality and potentially even functionality.

The Future of Car Mold Surface Textures:

Car Mold Surface Textures As automotive design continues to evolve, so too will the techniques and possibilities for car mold surface textures. We can anticipate:

- More Complex and Customizable Textures: Advancements in laser texturing and additive manufacturing will enable the creation of even more intricate and personalized textures.

- Integration of Functional Textures: Textures that go beyond aesthetics, offering enhanced grip, improved aerodynamics, or even integrated sensor functionality, may become more prevalent.

- Sustainable Texturing Solutions: The industry will likely explore more environmentally friendly methods for creating mold textures.

- Digital Texturing and Simulation: Advanced software will allow designers to visualize and simulate the tactile and visual impact of different textures with greater accuracy before physical mold creation.

In conclusion, car mold surface textures are a critical yet often overlooked aspect of automotive design and manufacturing. They are a testament to the intricate level of detail and engineering that goes into creating the vehicles we drive, influencing not only how they look and feel but also how they perform and endure. The careful consideration and precise execution of these textures are essential for delivering a high-quality and compelling automotive experience.